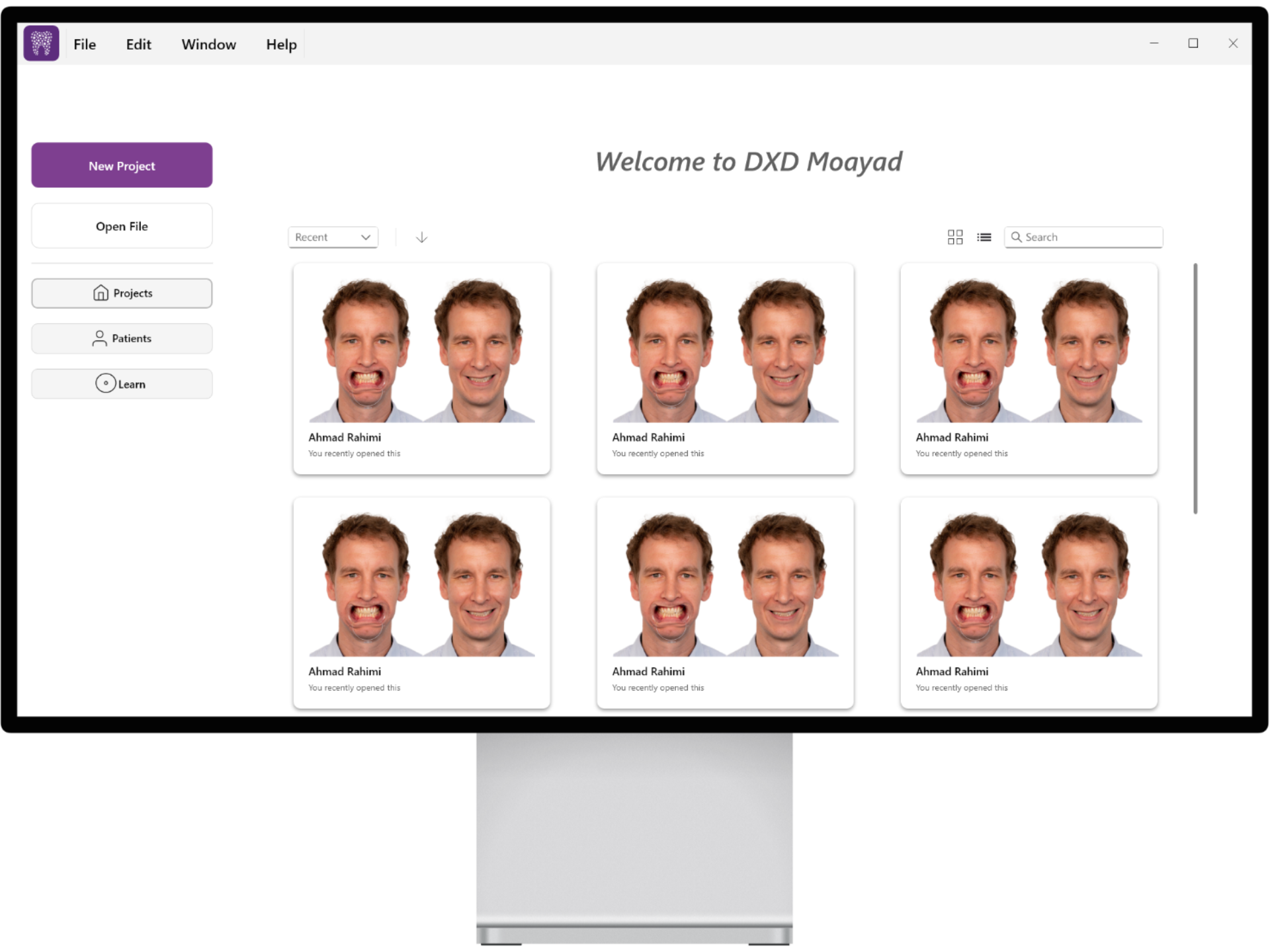

Case Study · Product Design · Desktop App

Dental Express Design Project Overview

We used the Jobs-to-Be-Done approach to build a focused V1 of a desktop smile-design tool. The goal was simple: reduce setup friction, shorten the time to a first reviewable design, and increase the chance that the first printed try-in matches what was approved.

Impact in Numbers

Chair-time to design

68min → 49min

First-print match

72% → 90%

Setup time

23min → 18min

Corrections per case

7 → 3.5

The Context

Clinics work fast in 2D tools; labs need precise 3D models. Rebuilding a 2D plan in 3D often caused drift, more iterations, and slower approvals.

The Challenge

The brief was to ship a resellable product that aligns clinic and lab expectations, uses standards-based exports, and produces a try-in that matches the approved plan - on a tight schedule with a two-person team.

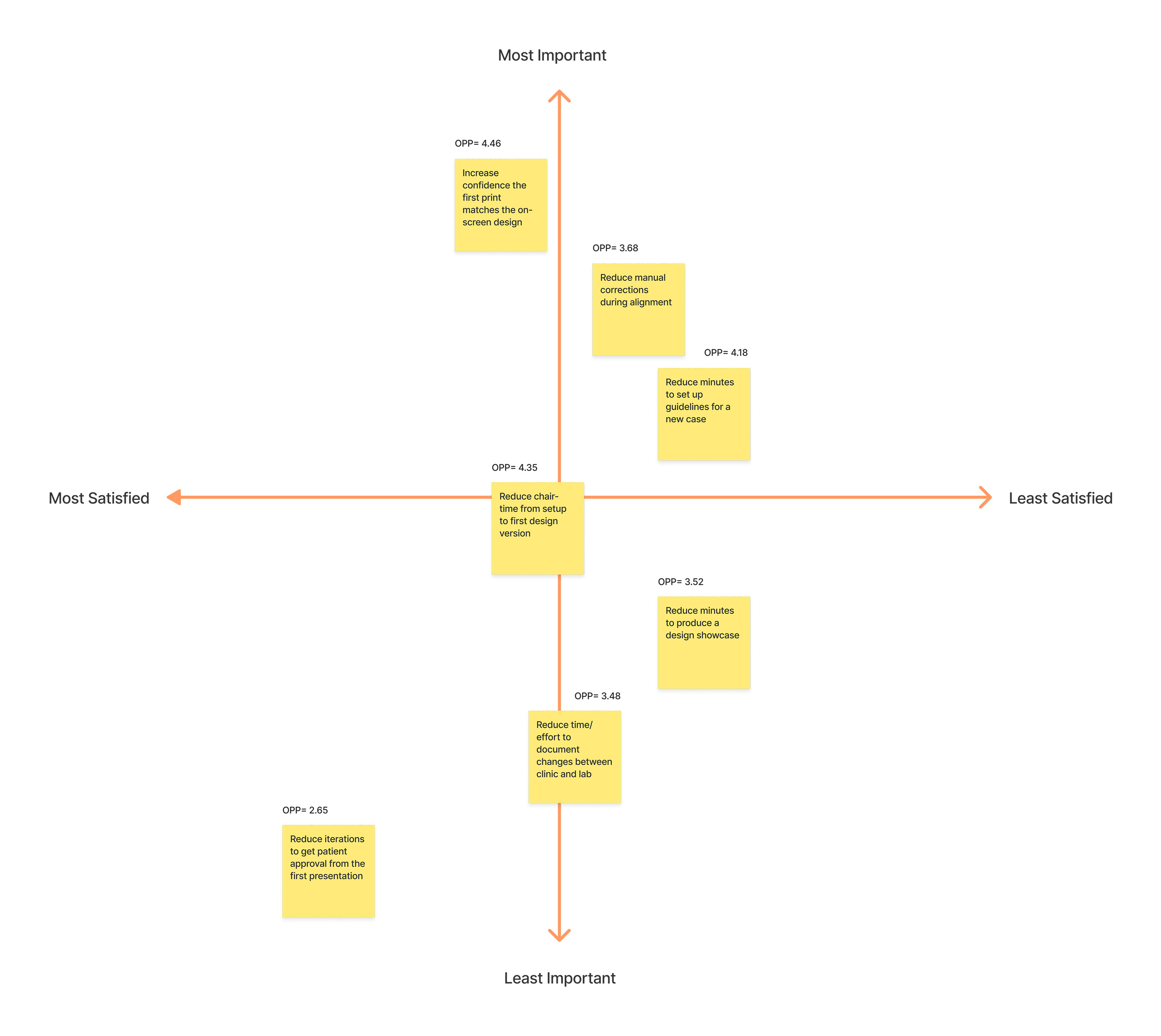

What We Learned

Clinics work fast in 2D tools; labs need precise 3D models. Rebuilding a 2D plan in 3D often caused drift, more iterations, and slower approvals.

What Changed in V1

Key design moves to improve the experience and efficiency.

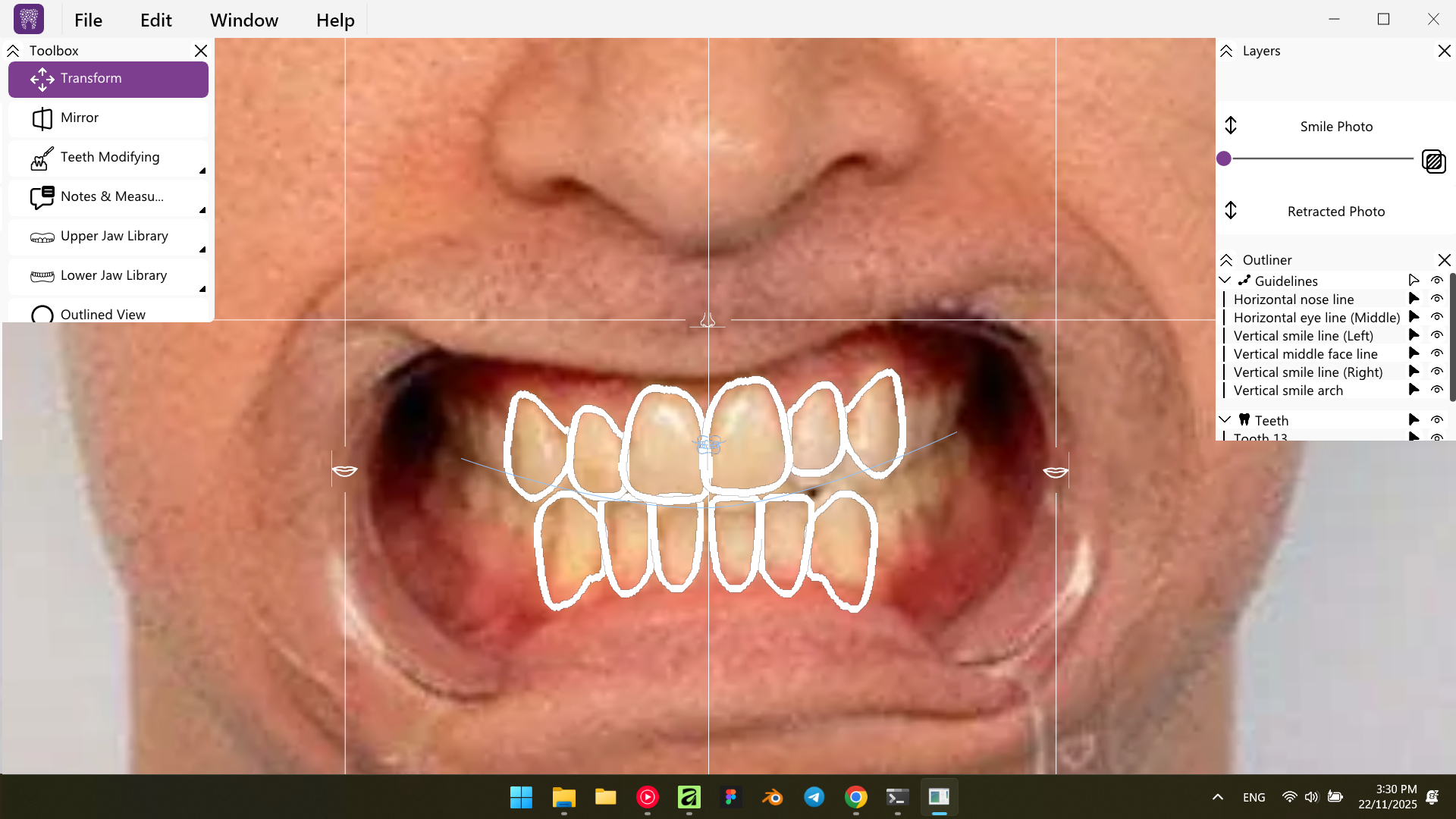

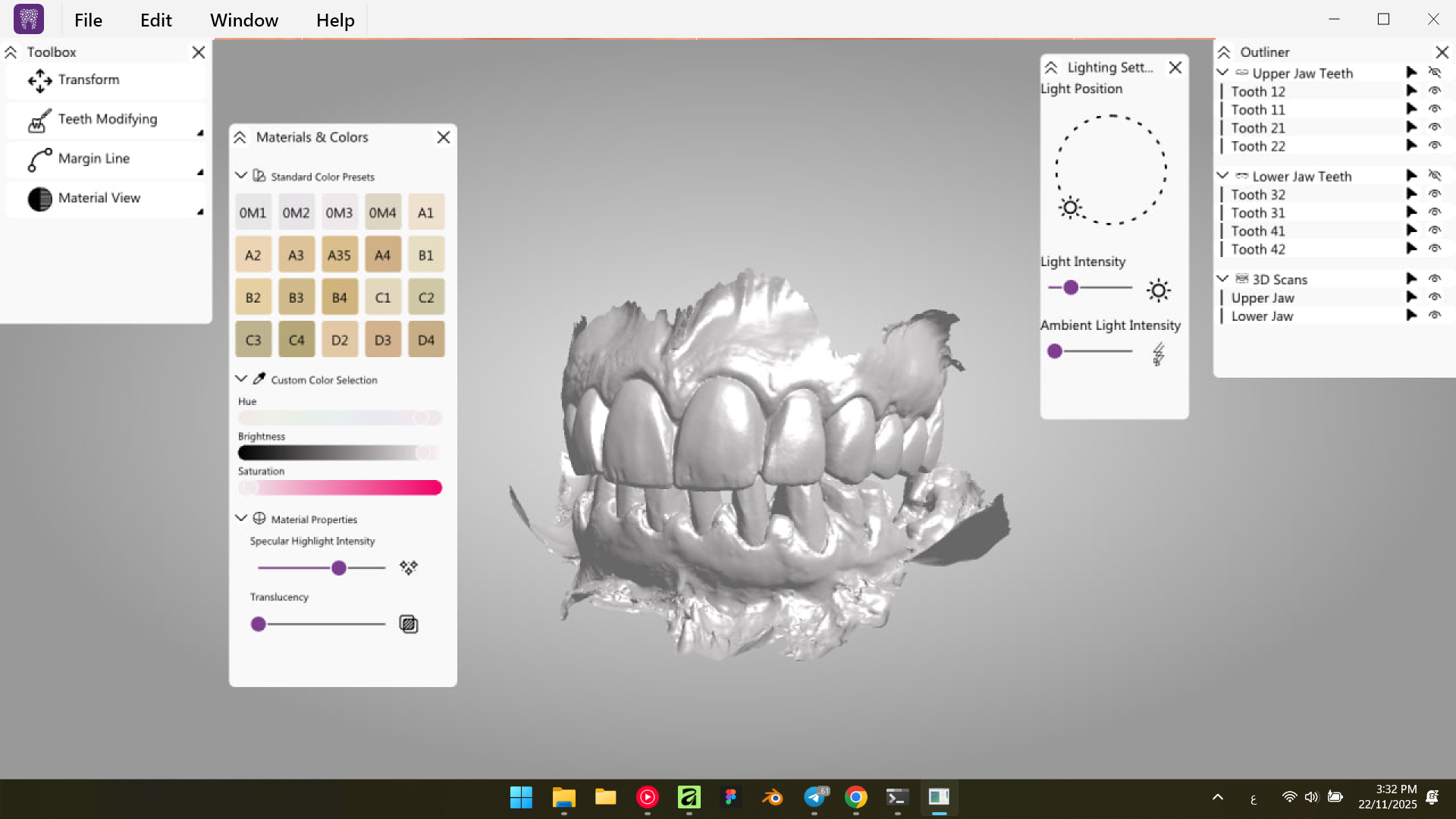

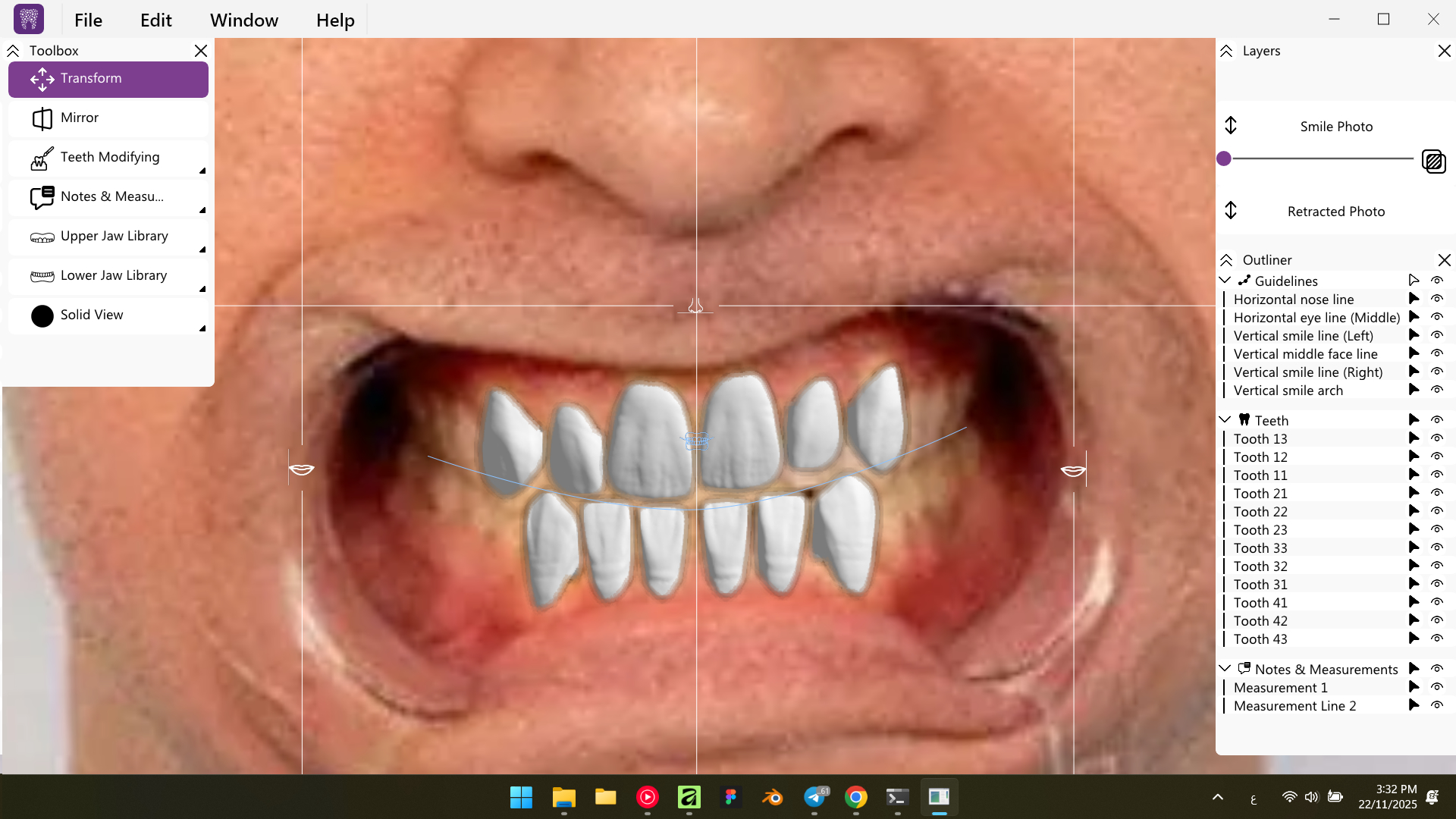

1) 2D/3D in one tool

Clinicians can make fast, precise edits with familiar 2D curves and overlays that act directly on the 3D model. Lab technicians can open the same case and continue with detailed 3D work.

Scroll to see more →

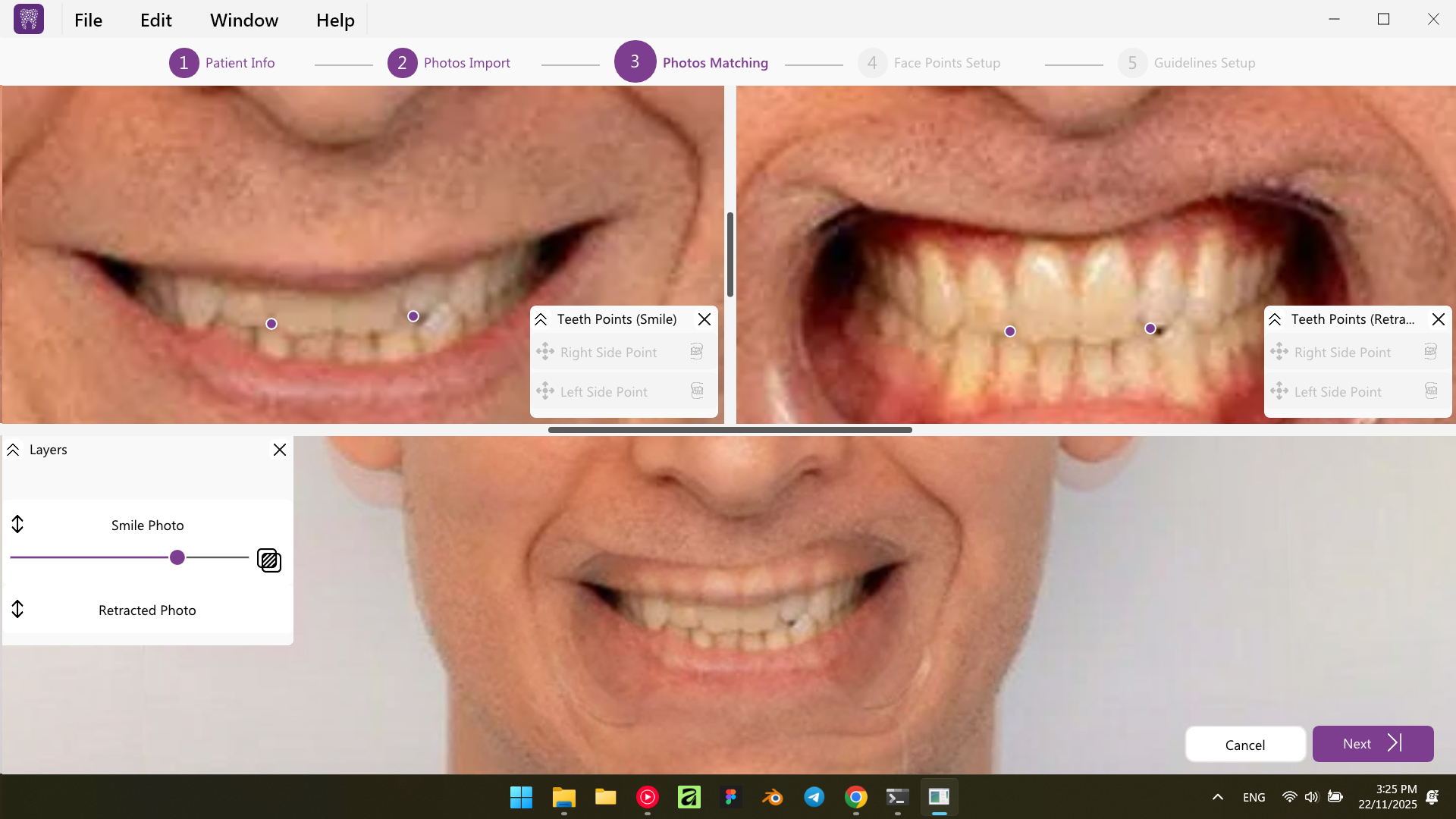

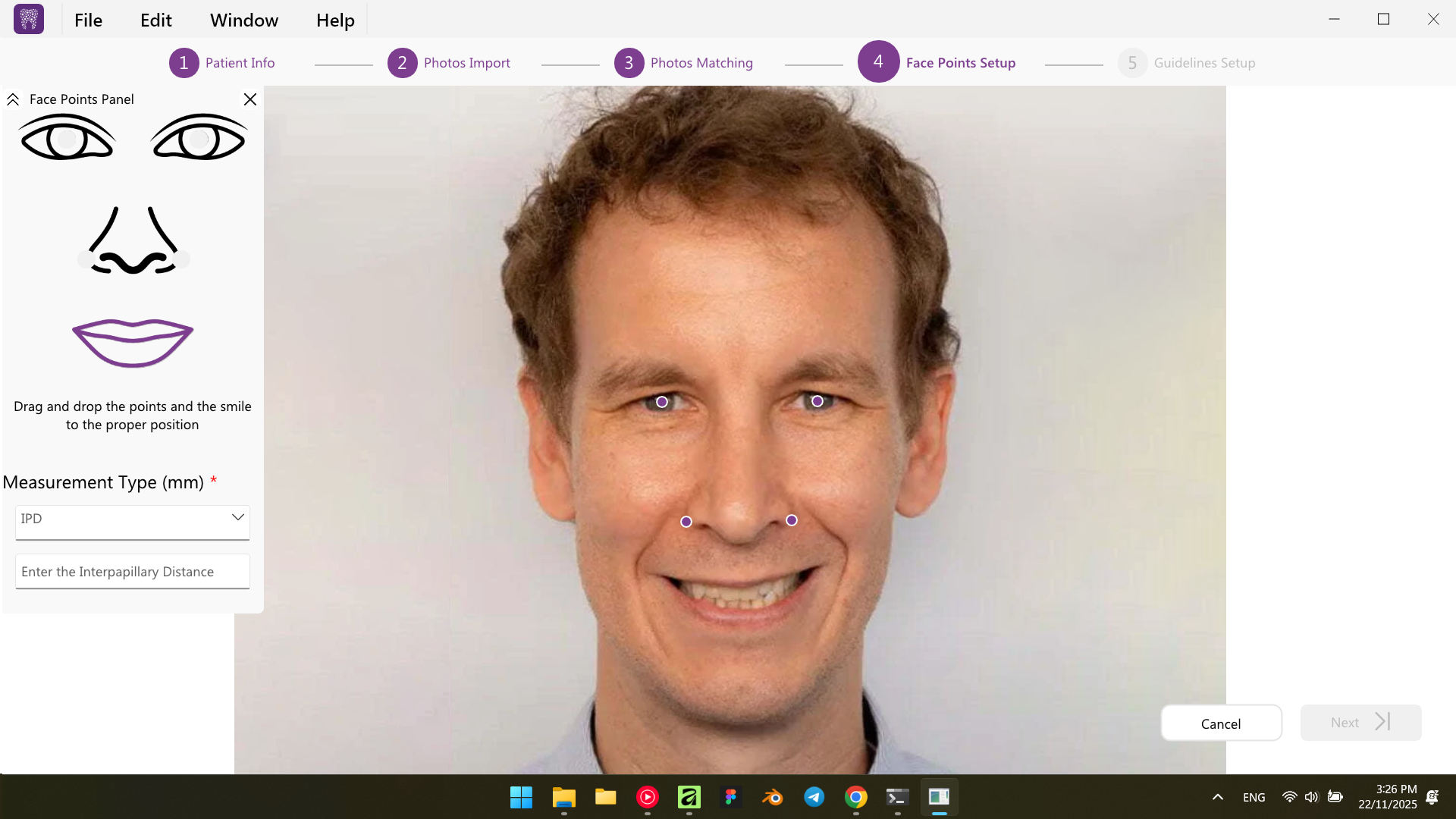

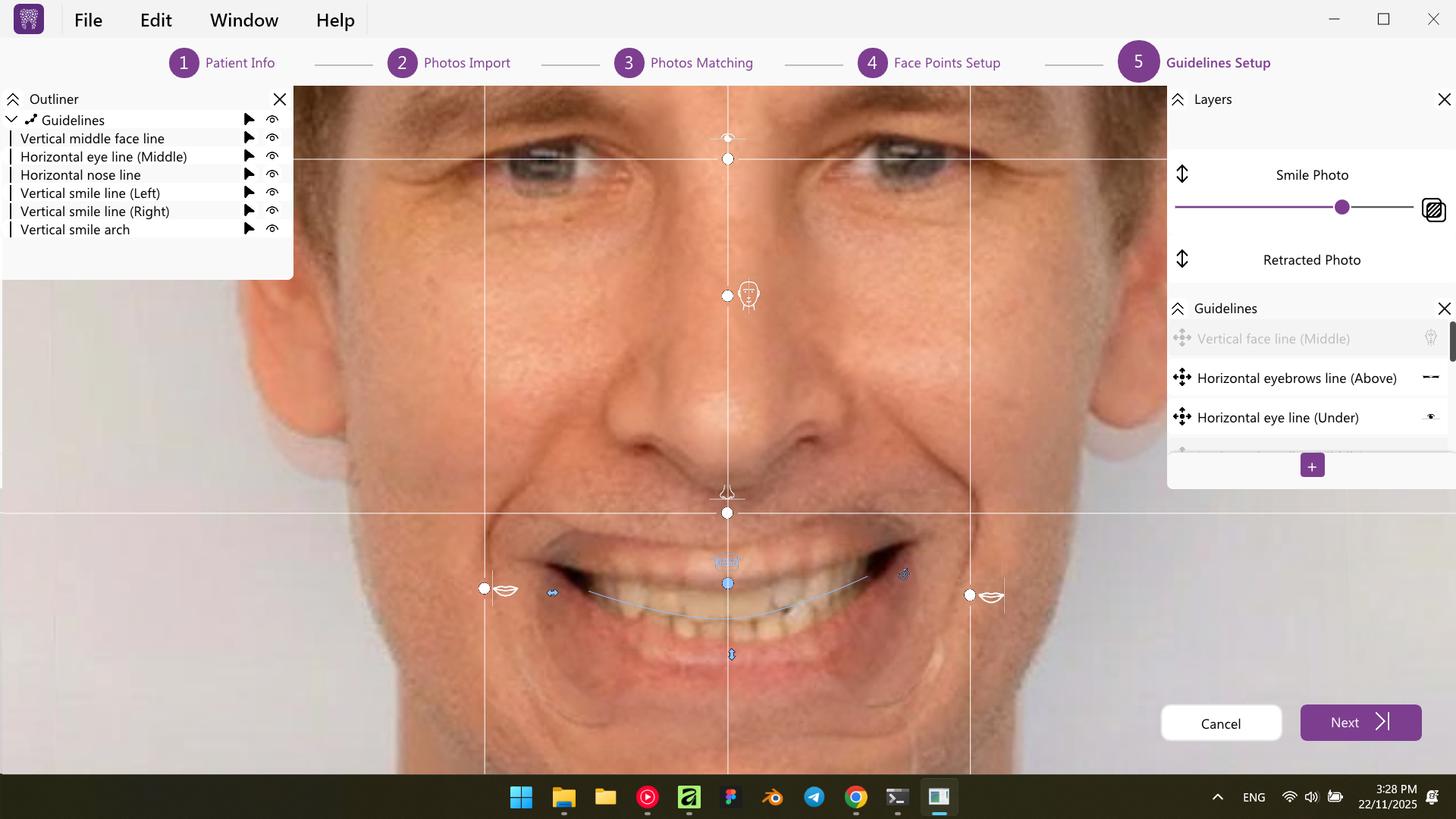

2) Faster guideline setup

Project setup spans several screens, including a dedicated Guidelines screen. Entering real measures triggers automatic placement of key facial guidelines.

Scroll to see more →

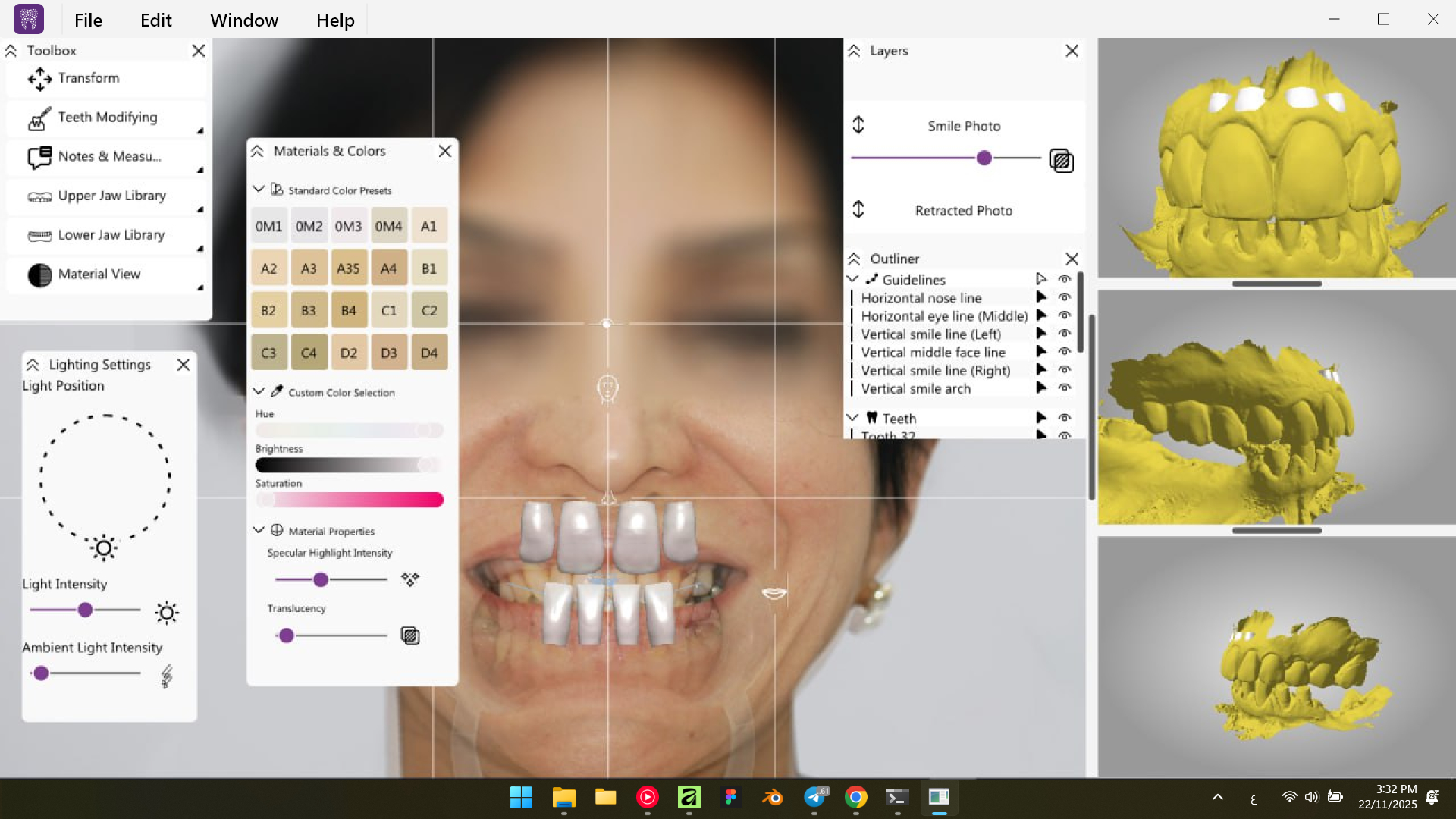

3) Quicker path to reviewable design

Two things made this faster: quicker Prepare (thanks to auto-guidelines) and a simplified, sufficient set of design tools with sensible defaults.

Scroll to see more →

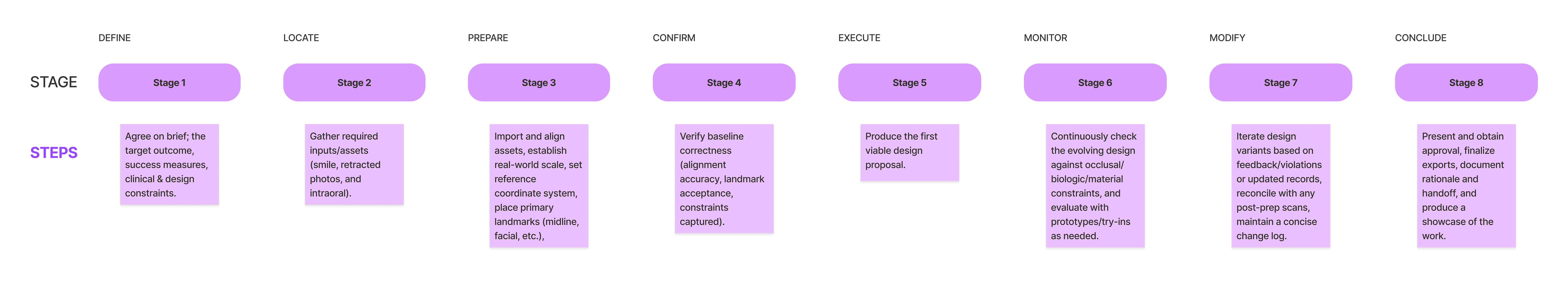

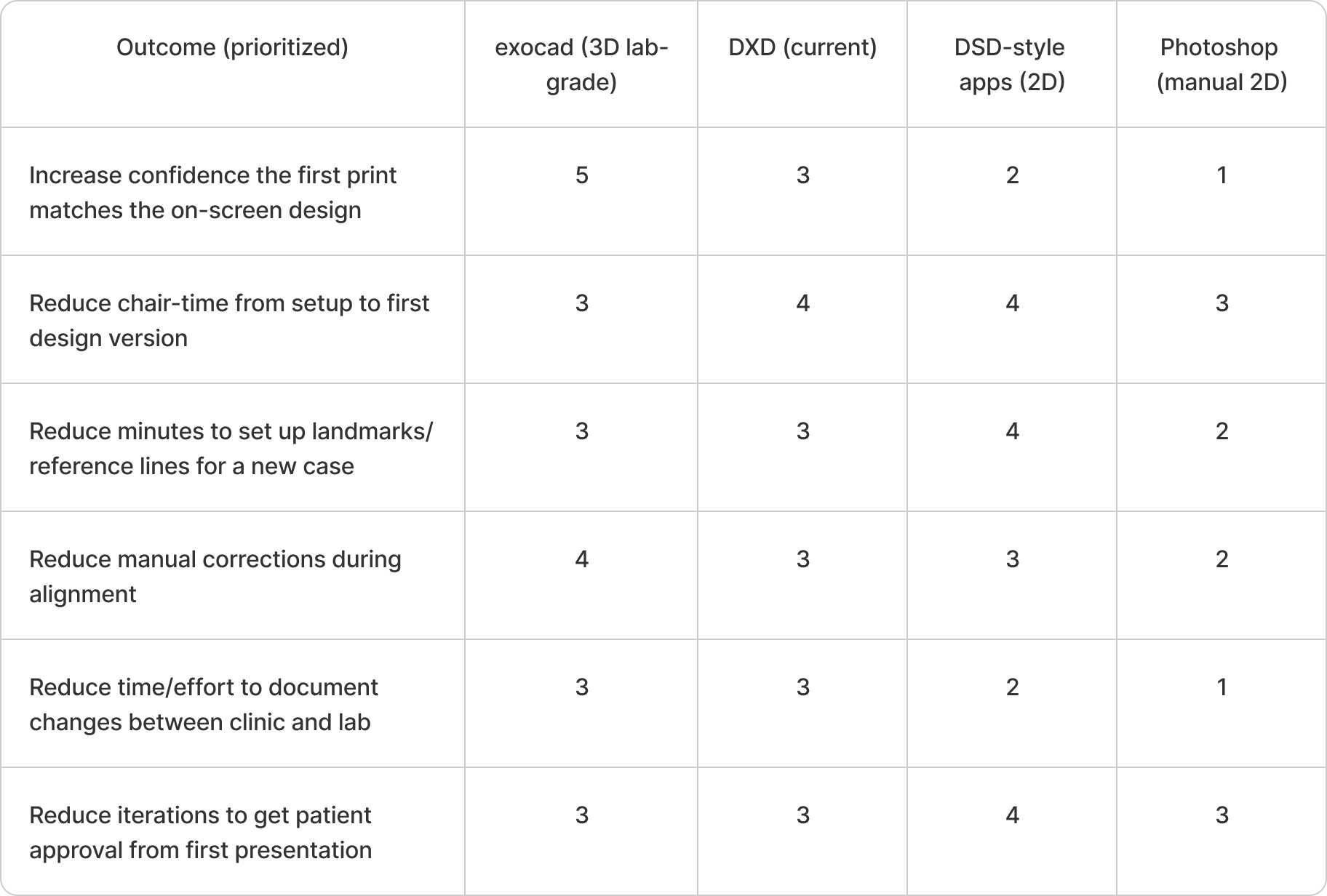

How We Validated

Rigorous testing through interviews, surveys, and a pilot program.

Methods included seven interviews (2 Exocad, 3 DXD, 2 other tools) with a recent-case walkthrough and one live case for timing; an importance vs satisfaction survey; a competitive coverage grid; and a 10-case pilot for V1 measurements.

Results from the Pilot

Measuring the impact across 10 pilot cases.

First-print Match

Using one tool avoids a 2D-3D rebuild, significantly reducing mismatches after handoff.

Chair-time

A simplified toolset and sensible defaults reduced the time to a first reviewable design.

Setup Time

Automatic guideline placement and presets streamlined the initial setup process.

Manual Corrections

Better initial automated placement reduced the need for manual adjustments.

Relevant Links

Explore more insights and details from this case study